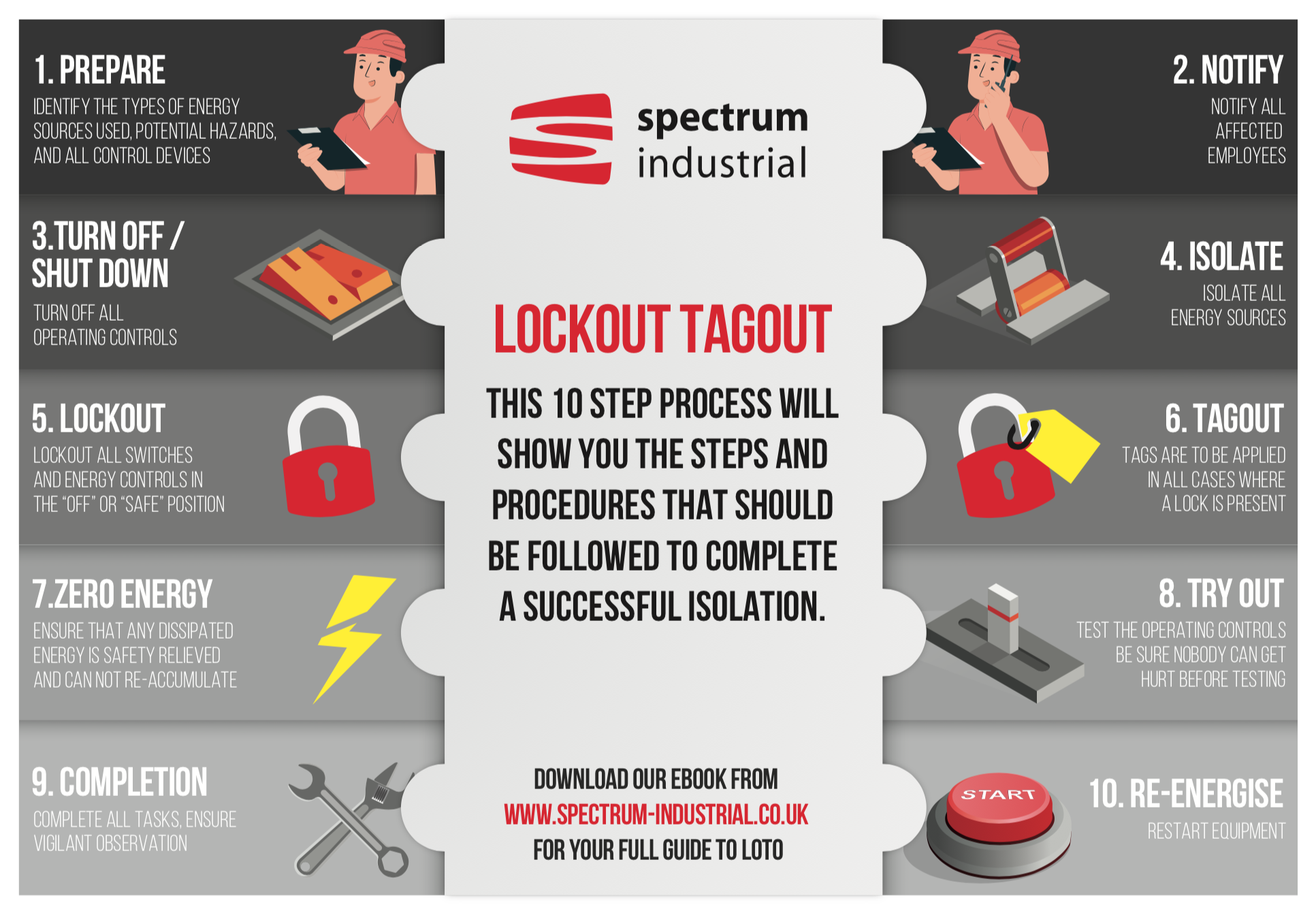

Essential Steps of Lockout Tagout

Posted on: 02/12/2023, 12:00

Essential Steps of Lockout Tagout

Lockout Tagout is essential in the control of hazardous energy, in a wide range of industry sectors. The unexpected start-up or release of stored energy is immensely dangerous for any employee/operative in close proximity to the machine. LOTO is still the best-known practice for this protection and should be utilized any time the machine is being cleaned, maintained, and inspected. As well as for company shutdowns, turnarounds, power outages and more.

LOTO process/procedure steps - Click here

Top Lockout Tagout Tips to Follow

- Clearly identify padlocks and tags either

personally or departmentally.

personally or departmentally. - Allow time & apply actions to relieve any stored/residual energies.

- Ensure Lockout equipment is suitable for the intended task.

- Develop a written programme, with process & procedures with all details that MUST be followed.

- Any new machines must have a written programme/procedure developed against it.

- All new & existing staff are to be trained and made aware of LOTOTO, it’s dangers and how to implement safely. According to the standard operating procedure (ongoing activity).

- The only person to remove a lock is the one who applied it.

- Implement and review the Lockout Tagout process and procedures annually. Update and improve where required.

- You must Try-Out every time. Confirming the success of the isolation before proceeding with the task.

Lockout Tagout Regulations

LOTO is governed by strict regulations UK wide – hse.gov.uk

- HASAW 1974

- Electricity at work Regs 1989

- PUWER Regs 1998 – Reg 19 for isolation from Sources of Energy

- Quarry Regs 1999

- OSHA 1910.147 – Control of Hazardous Energy – osha.gov

The purpose of these regulations is to prevent injury and fatality. Contact with moving machinery and isolation (including stored energy) is still in the fatal 6, identified high consequence hazards.

Employers must develop, implement, and enforce an energy control program in line with regulations. As well and providing the correct Lockout Tagout equipment to fulfill the procedures in place.

Risk assessment

Lockout Tagout is a process designed to reduce/eliminate risk, when performing high risk tasks. A risk assessment should be conducted each time a task occurs with potential risk. The machine/task specific written energy control procedures will ensure every task has the risk assessed before any action commences. Potentially a one-off task outside of the norm can arise, meaning any works on said task should have a risk assessment conducted by a qualified & authorized representative to control this project. A newly written energy control program should be completed in case of a future re-occurrence.

Lockout Tagout Safety Checks

Audits and visual inspections should be regularly carried out by a competent person, following the specific guidance outlined through regulations and company process/procedures. At least annually, a full audit and site survey should be completed to ensure that all equipment is of high quality, in good working order & in the required volumes to complete tasks. Additionally, the audit should cover and fulfill any newly updated/improved regulations.

It’s also worth noting, any new piece of machinery on site which will require isolation and its energy controlled. Should have a standalone machine specific energy control program written against it (working closely with the manufactures guidelines on its energy sources and moving parts) and trained out to all affected employees. All new employees should be trained to the level of every operative on site with ongoing updates, competency checks and refresher courses conducted.

Conclusion

Lockout Tagout is not an optional activity! The responsibility to govern this within establishments begins at the top. To instill the culture, behavior, and awareness to a high standard throughout. Remember “Short cuts, may cut a lift short!”.