Avoiding contact with Moving Machinery!

Posted on: 14/12/2023, 11:15

Avoiding contact with Moving Machinery!

Contact with moving machinery is still in the identified fatal 6 high consequence hazards.

What better time than in the UKs National Safety Month to look at how to best protect your employees with a mini guide on avoiding contact with moving machinery.

LOTO expert Alex Baker takes a look at machinery safety.

Being one of the highest percentage risks for injury and fatalities in a wide range of industries, measures are often being reviewed, improved, and regulated to ensure avoidance of contact with moving machinery. One best practice is to ensure the adoption of a systematic & holistic approach of managing risk and implementing a safety culture across all employees, especially the affected ones.

Why is machinery safety important?

Why is machinery safety important?

Sounds like a simple question but there are many ways injuries can occur:

- Crush injuries.

- Struck by moving parts or ejected parts of machinery.

- Severing, slashing, puncture, and abrasive injuries.

- Being dragged into a machine by loose clothing or jewellery.

- Burns from chemicals or heat sources (both hot and cold).

- A lack of training for employees and faulty machines are also

a huge contributor to such injuries.

What do YOU have to do?

What do YOU have to do?

Employers should already have a Safe System of Work (SSoW) and Energy Control Programme (ECP) in place for each machine and a safe isolation procedure to suit. Additional to this you should also:

- Check all guarding protocols including Interlocks, Maglocks, Light-Curtains etc. are all in good working order and complete.

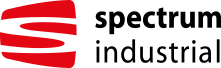

- Follow the 10 steps of the LOTOTO process in accordance with the Energy Control Programmes and by using the correct equipment to isolate machinery safely.

Also ensure that you have checked that all energy sources are fully turned off, isolated, and guarded.

These can cover but not limited to:

- Electricity

- Hydraulic pressure

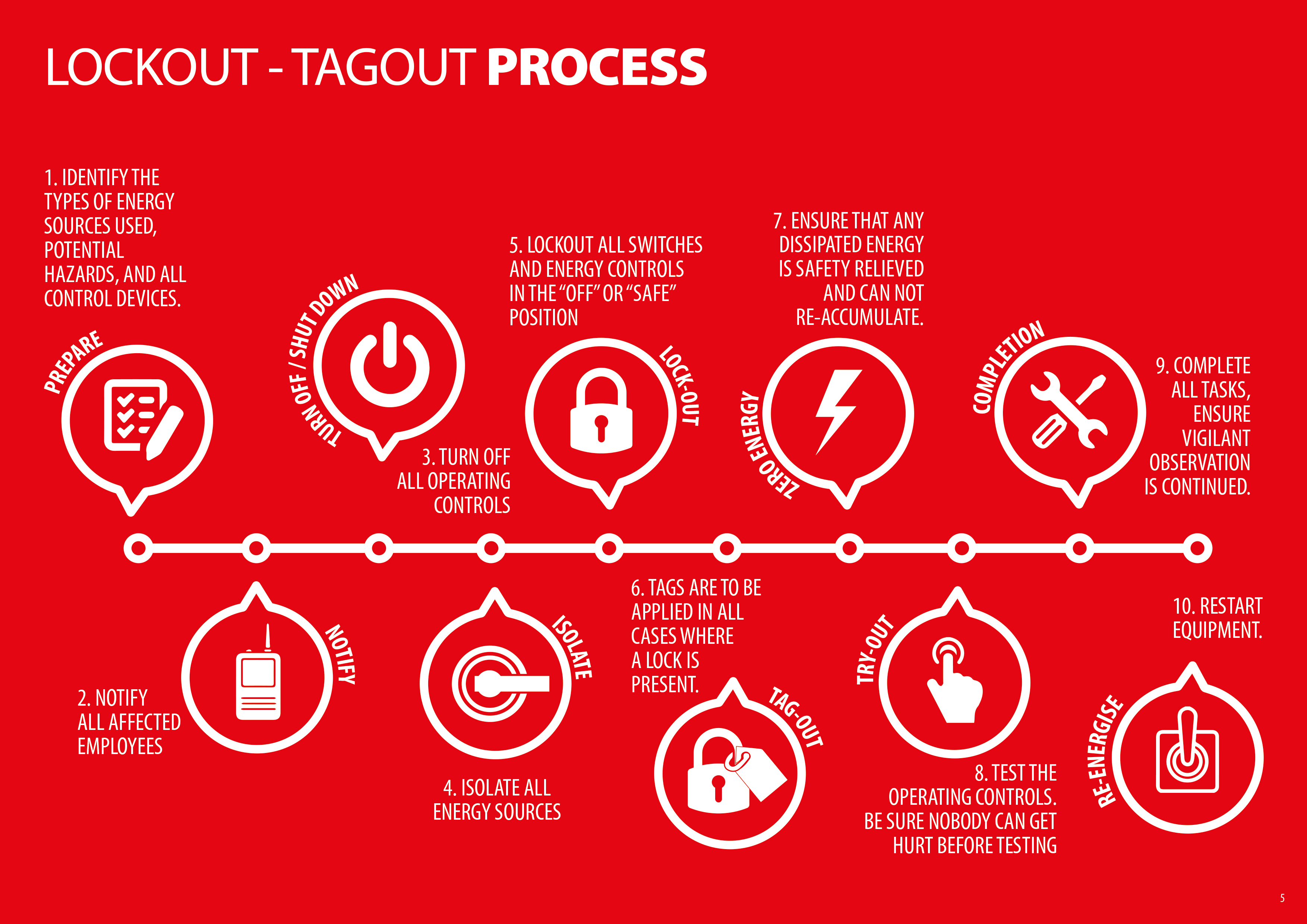

- Pneumatic pressure/Steam

- Kinetic movement – Conveyors

- Liquids – gasoline or other fuels, chemicals, and water

- Gases – poisonous, suffocating, and explosive

- Gravity – Falls from height (Steep Conveyors), falling parts, or mechanisms that work with or against.

- Spring tension

- Moving parts – fans, belts, gears, saw blades, and presses

Be aware that the energy can often be controlled automatically on timers or through sophisticated software systems. Meaning that whenever changes or updates take place in these set-ups, a newly updated ECP and SSoW should be updated and implemented as it would with any new piece of machinery.

Always remember, never:

- Use or attempt to use/start a machine that has lockout tagout applied. Even if it seems to make the task easier to complete or it appears that everyone has left the risk zone. This could, and has, cost a life.

- Remove, adapt, or bypass safeguards, they are there for a reason and should remain fixed unless the task requires the adaptation. Which should be permit controlled with an authorised person managing the tasks risks with appropriate and sufficient LOTO applied.

- Tasks are dangerous, never distract a fellow operative!

What is LOTOTO:

- Lock-Out

The placement of a personal lock on an isolating device in such a position that prevents the operation (i.e., movement) of the isolation device and energisation of EQUIPMENT until removal of the lock in accordance with established procedures.

- Tag-Out

Placing a tag on a lock or point of isolation to identify who placed the lock and when it was placed.

- Try-Out

The attempt to energize or start-up EQUIPMENT that has been fully isolated to verify that it is completely de-energized and inoperable

LOTOTO refers to a safety procedure that ensures dangerous machines & energy sources are properly shut off, controlled, and locked out to prevent the unexpected start up before the completion of tasks or servicing.