Why isn’t Lockout Tagout taken more Seriously?

Posted on: 19/12/2023

Why isn’t Lockout Tagout taken more Seriously?

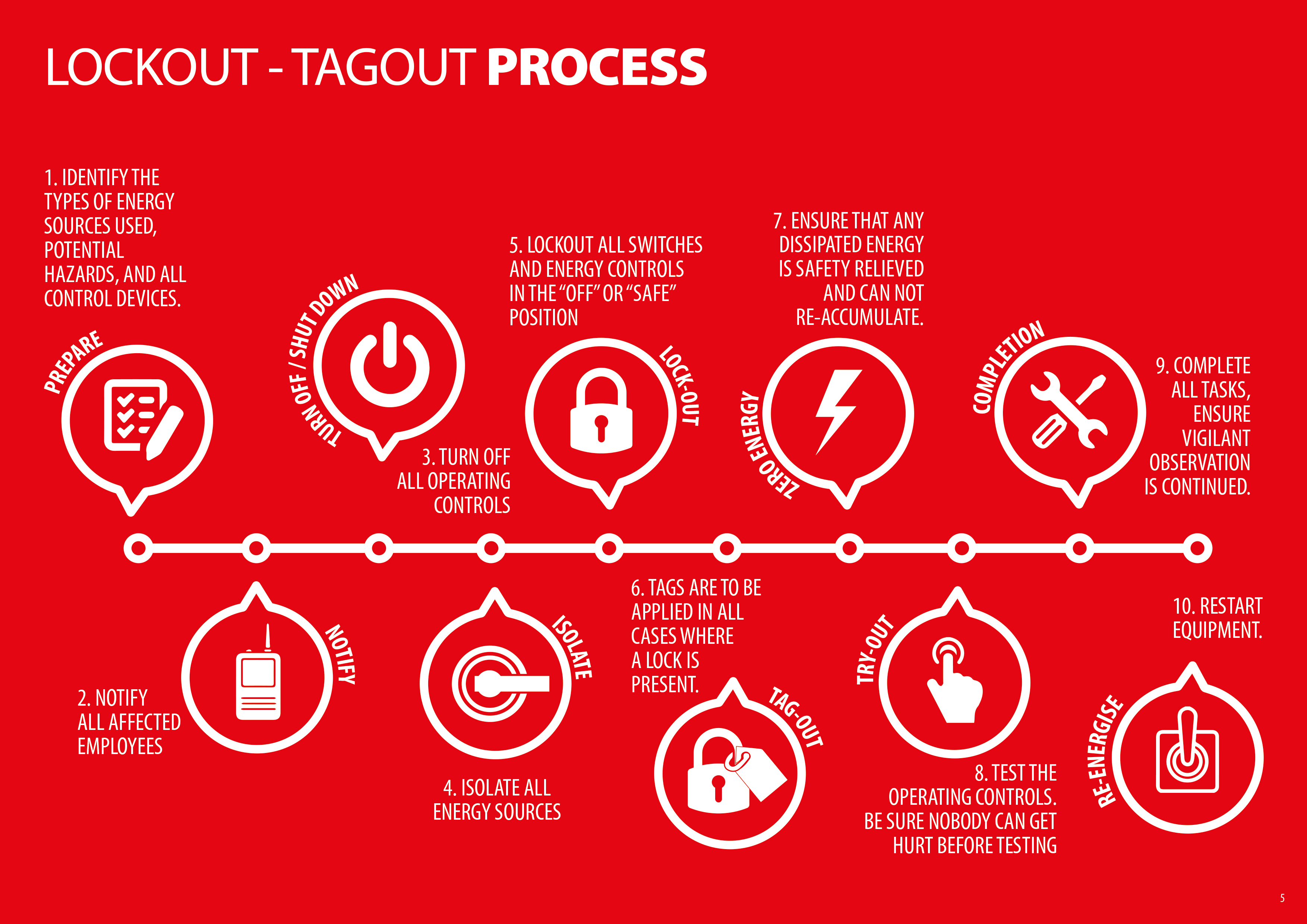

Lockout Tagout is the best possibly practice for the control of hazardous energy in any establishment where these types of dangers present themselves.

Did you know? 111 workers killed in 2019/2020 in workplace accidents, 69,208 non-fatal injuries reported by employers

www.hse.gov.uk/statistics

Every year, a huge number of workers are killed in workplace accidents which could have been prevented. Additionally, accidents that didn’t result in a fatality, ranging from a scratch to an amputation and everywhere in between account for 10s of thousands of reported accidents. Once again, the majority of which were preventable through means such as the Lockout Tagout process & procedure.

It’s estimated that 120 fatalities and around 50,000 injuries are actually prevented directly due to the correct use of LOTO on hazardous energy every year. Yet, Lockout Tagout still seems to only be used to a fraction of the levels that it should be.

The largest failings are

- Failing to provide training & awareness to new and existing employees.

- Failure to produce an appropriate energy control programme or simply not producing one at all.

- Failure to conduct regular audits on site for changes in machinery, to highlight areas of improvement and to ensure up to date regulations are adhered to.

- Failing to use or have available the Lockout equipment & devices at all.

The costs relating can be huge for the company and affected employees. Not to mention the psychological impact for anyone involved.

It raises the question that, should we do more as an industry to help promote LOTO awareness and its benefits? However, looking into what’s readily available with some simple searches or conversations/assistance from someone experienced in the field. The act of planning and using LOTO is simple and shouldn’t scare away employers from implementing such beneficial equipment & procedures.

The failings are vast in a huge number of establishments but LOTO should be a staple process for anyone, any business and any application that require it. Once they do, the totally preventable injuries & fatalities should plummet. Along with the associated costs, physically, mentally & financially.

Lockout Tagout as an application process provides a physical and visual preventative measure to the task at hand. It shows that someone qualified is performing a task on the machine with relevant information to the individual and the task. As well as a lock to prevent the re energisation of the machine should someone wish to try override it (in no circumstance should this happen, but the protection is provided either way). Of course, this isn’t a one size fits all solution and some tasks will require more complex lock/tag/equipment applications, which should be outlined in the company’s energy control programme.

Regardless of how successful LOTO is on paper. Employers should always ensure that the human element is minimised to its maximum potential. Human error accounts for a huge amount of workplace accidents in all forms and mistakes will always happen no matter how many preventative measures are in place. That said, with the right training, approach and outlined steps. The compound effects from inevitable mistakes will be reduced, hopefully to where it reveals zero injuries.

LOTO is a highly competent process even in its simplest form and does, to a degree, naturally take out a human element. However, a quality process, procedure and energy control programme should always be present so everything can work in harmony.

All told, LOTO is simple to use, is the best possibly practice and saves a huge number of lives. Nothing is more beneficial than that and we should all take the sector more seriously, so every establishment is equipped and trained to a competent level worldwide to keep those fatalities and injuries on the decline